Building a wooden raised vegetable bed frame is cheaper than buying a ready made raised bed and is a relatively simple exercise, but for those unsure about how to go about building one below is a step by step guide on how to do it.

- 4.5 OR 5 MM DRILL BIT

Preferably long but the standard length is adequate. - HEX SCREW BIT

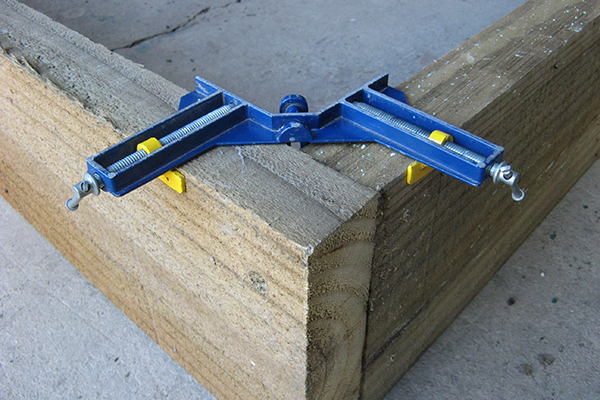

Only if using bugle baton screws. - 90 DEG. ANGLE CLAMP

One is adequate but four will make things a little easier. - POWER DRILL

- CIRCULAR OR HAND SAW

- SET SQUARE

- 100 MM BUGLE BATON SCREWS OR 125 MM GALVANISED BULLET HEAD NAILS

Other types of screws can be used but I have found bugle baton screws to be ideal as they are robust enough not to break under tension and sit flush with the timber, no unsightly knobs. - 4 200 X 50 MM LENGTHS OF TREATED OF PINE, REDGUM, SUGAR GUM OR JARRAH

The lengths of the timber will depend on what length and width raised bed you want to build.

TOP PHOTO : Long drill bit, standard 5 mm drill bit, and Hex bit designed to screw in bugle baton screws.

BOTTOM PHOTO: 125 MM galvanised bullet head nail and 100 mm bugle baton screw with an inset showing the actual head. Both are suitable for securing 50 mm wide landscaping timbers.

I prefer to make my frames on my flat garage floor then move them as a single piece to where I want them to be placed. Though if the land is flat where you want to build the raised bed it can be made on site.

1. clamp the frame together

On a flat piece of ground clamp the corner of two pieces of timber to form a rectangle.

2. Drill the pilot holes

Drilling pilot holes makes it easier for the screws or nails to go in, but make sure that the pilot holes are narrower than the screws or nails to be inserted. Though note that the hole does not need to be as deep as the length of the nail or screw, about two thirds as long is ideal. The pilot holes are there to ensure that the nails go in straight and to reduce the risk of the screws jamming. Pilot holes are especially important when using hardwoods such as redgum.

3. Drill or nail the ends together

Drill or nail the clamped ends together using the pilot holes as guides. Once the ends have been secured the clamp can be removed.

Repeat the process for the other three corners. If you have four clamps you can put the entire frame together before screwing or nailing. It is possible to build a frame without a clamp but even one clamp makes the job a lot easier.

The maximum length of landscaping timbers is three metres, so if you want to make your raised bed longer than three metres you will have to join two lengths together. There are two basic ways to do this.

- STEEL SLEEPER PEGS

Sleeper pegs make it relatively easy to attach two sleepers together. To attach sleepers to a sleeper peg drive the peg into the ground where the sleepers are to be joined and simply screw the two ends to the peg. There are a variety of sleeper pegs on the market of different lengths and heaviness. The main disadvantage of sleeper pegs is that they are expensive. - LANDSCAPE TIMBER OFFCUTS

A cheaper alternative to sleeper pegs is to use landscape sleeper offcuts. The offcuts need to be about 60 cm long (40 cm of the offcut sticking into the ground) to ensure that the sides do not bow out under the pressure of the soil in the raised bed. The main disadvantage of using offcuts is that they are more conspicuous and take longer to put in place as holes have to be dug before putting them in.

TOP: Steel sleeper peg being used to hold two pieces of landscape timber in place. BOTTOM: Detail of a steel sleeper peg.

If you want to make a bed higher than 200 mm then simply make two identical frames and nail or screw them together.

A wooden raised bed that has had its height increased by 100 mm. It has been secured to the lower section with 150 mm bugle baton screws.